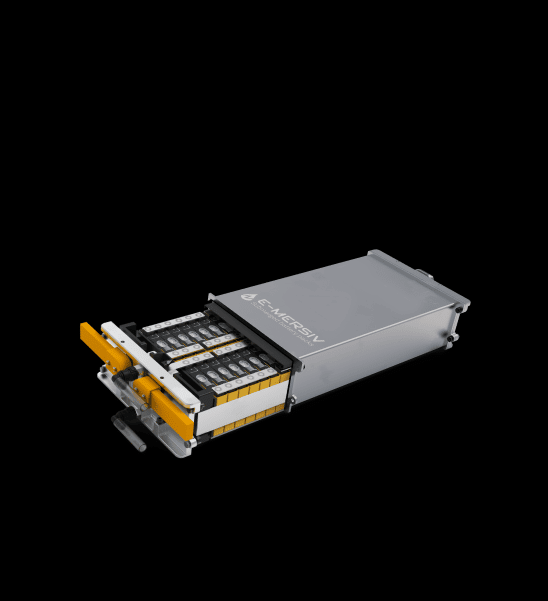

High performance battery packs

Values are representative of submerged battery packs that have already been developed and validated by E-MERSIV for our customers. Key figure for your application may differ according to cell chemistry or form factor.

unlocking the barriers to a rapid and massive adoption of EVs

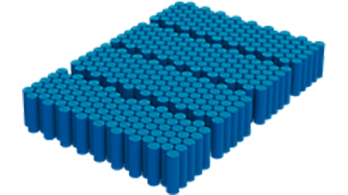

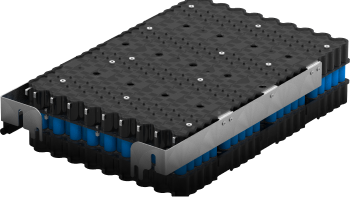

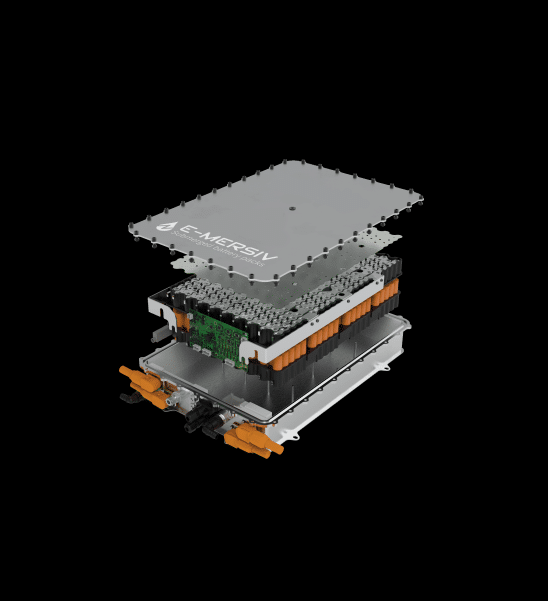

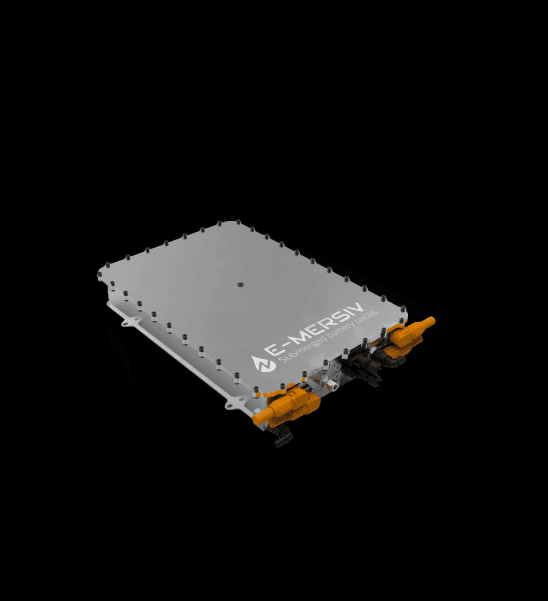

E-MERSIV develops and manufactures world class patented immersion cooling li-ion HV battery packs with the best cost-benefit ratio.

Our customers choose our products because of their performance, longevity and increased safety. We have tested our battery packs for over 150,000 hours to prove the superiority of this technology.

Extreme Discharge Power

More than 50C

Ultra-Fast Charging

< 10 minutes

Better Safety

100% Fully immune to thermal runaway propagation

E-mersiv unique selling points

Specific use cases

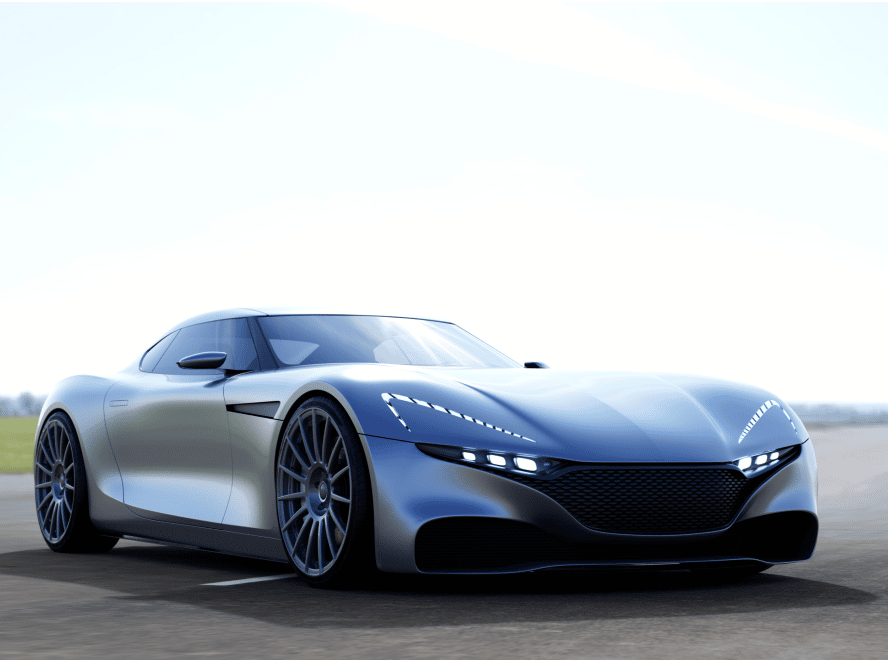

Sport car bev

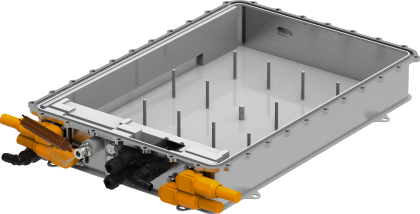

50kWh submerged battery pack

HEV premium sedan

Submerged battery pack of 7kWh

Your custom battery pack

Custom battery pack for extreme conditions

Contact Us

33170 Gradignan – France